Customer needs drive us to make Material Impacts.

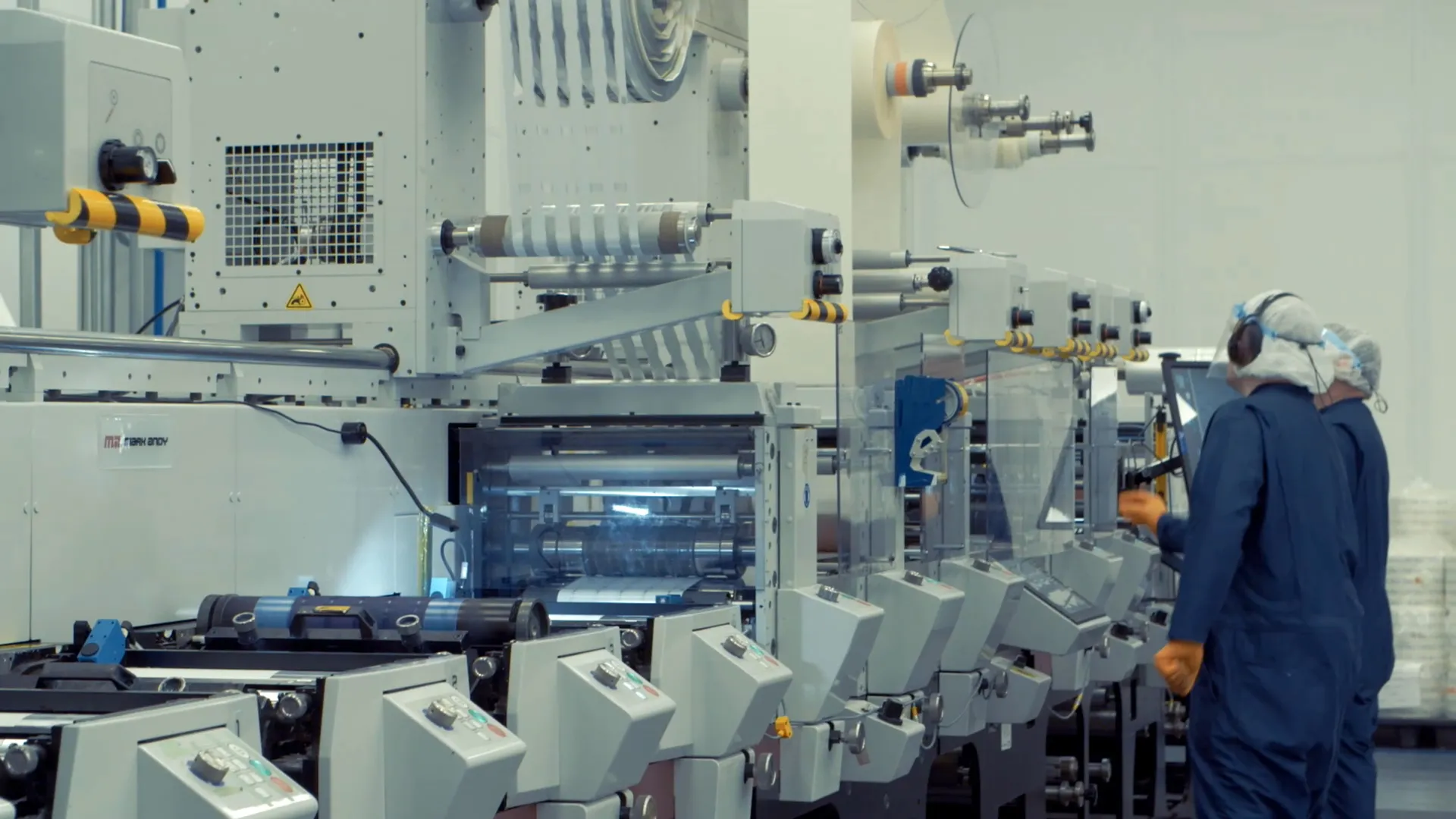

With leading science, engineering and manufacturing capabilities, at global scale, our teams deliver solutions that deliver results where it matters.

The Mativ family of brands

Leading producer of durable substrates for a variety of end markets

Specialist manufacturer of adhesive tapes for building professionals

Leading manufacturer of hockey tape since 1980

Consumer paper products for meaningful moments

Leading worldwide supplier of high-performance plastic materials

Bold, vibrant, colorful paper to bring ideas to life

Leading global manufacturer of specialty papers and sustainable solutions

Leading global manufacturer of bonding products and adhesive components

Global filtration solutions provider for a wide range of industries

Engineered polymer performance technology for the global specialty films marketplace

Leading extruded plastic manufacturer for consumer and advanced wound care applications

Trusted strategic contract manufacturer for leading healthcare and consumer companies

World-leading manufacturer of industrial netting for wide range of industries

Leading global coater and converter of high-quality paper and film release liners

Premium cover materials for security documents and key publishing markets

Our Solutions

Filtration & Advanced Materials

We’re protecting people, machineries, and the environment with our filter media, engineered films, nettings, cores, and tubes. With facilities on three continents, and our commitment to innovation, we help our customers make material impacts all around the world.

Sustainable & Adhesive Solutions

From submarine cable tapes to premium packaging to skin-friendly adhesives, our sustainable and adhesive solutions help our customers make material impacts every day. We push the limits of what’s possible to bring our customers’ visions to life and transform their ideas into results.

Technology

Advanced Coating

Advanced Converting

Apertured Films

Coating

Converting

Embossing

Extrusion

Lamination

Netting

Nonwovens

Paper & Natural Fiber

Saturation

See how our people and materials make material impacts on the world.

-

-

-

Looking Through the Smart Glass

A Conversation with Tom Niziolek – Mativ’s General Manager, Optical and Industrial Films & Tubes

-

Holding the World Together with Conwed Nettings

A Conversation with Dan Donohoe – Mativ’s Commercial Director, Conwed