Reinforcement

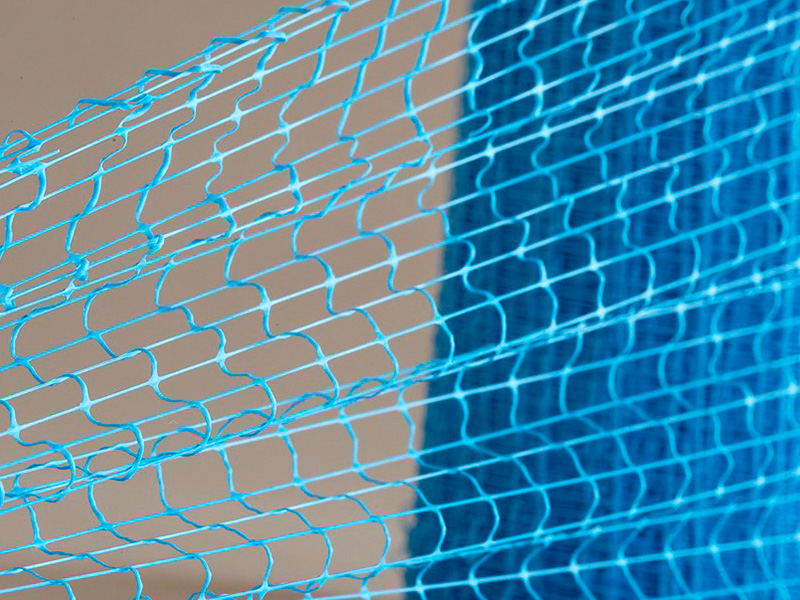

When it comes to reinforcement netting, Conwed can deliver superior strength with lightweight netting solutions.

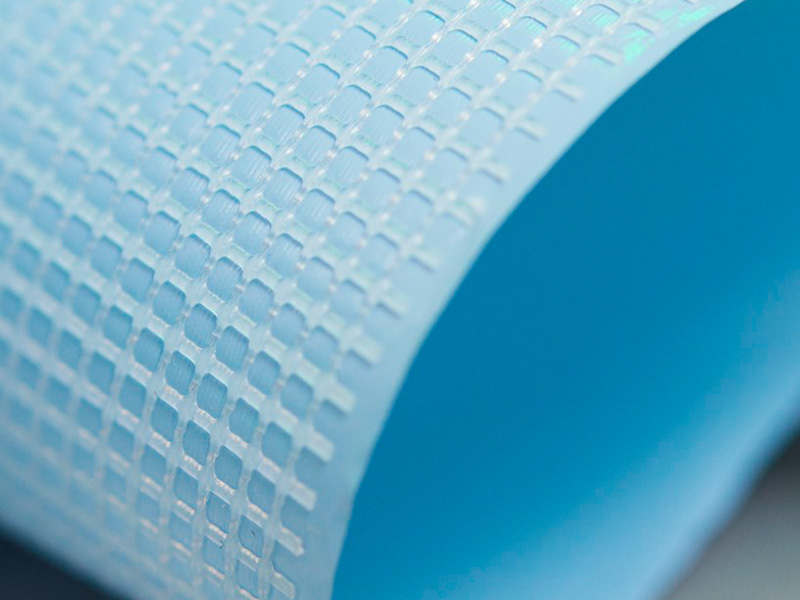

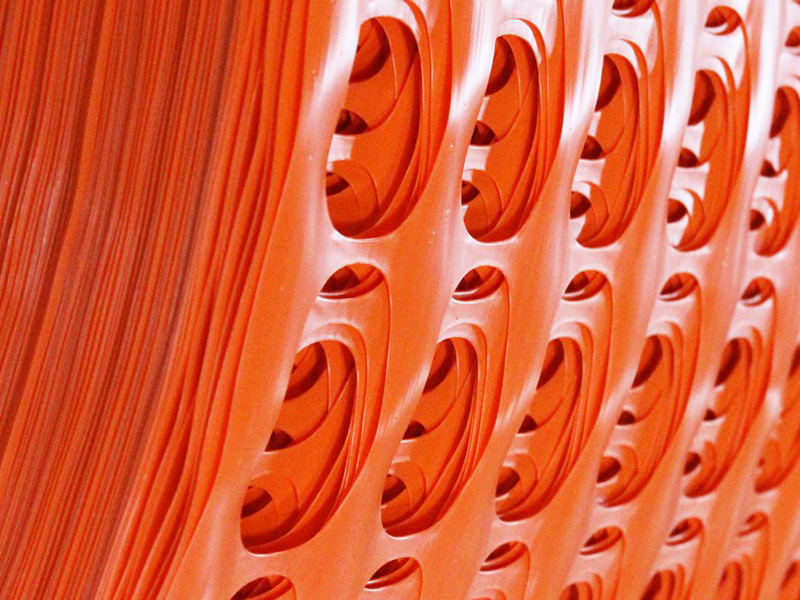

Conwed™ Reinforcement Netting can add strength and support to help products perform under the toughest conditions and in various applications. From reinforcing pet food kraft-paper bags to technically sophisticated nonwoven composites in medical, cleaning, and hygiene applications, our netting portfolio delivers versatile performance features. We continuously push the limits of our reinforcement netting technology to customize strength-to-weight ratios.

Our customers can reduce the overall product weight without sacrificing tensile strength. Many of our reinforcement applications use our netting to add an extra element of strength to the final product or in their production processes.

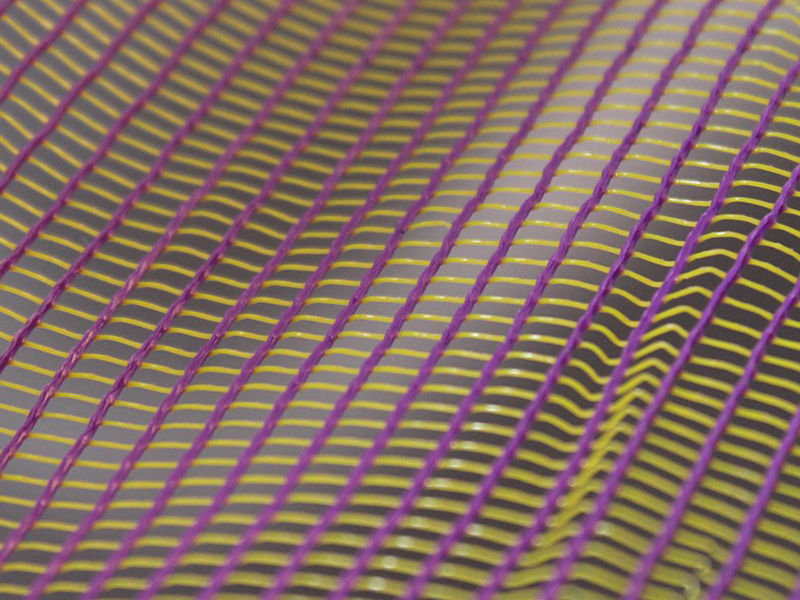

Co-extrusion is a multi-layer extruded netting that can subsequently be oriented where different polymers can form different layers on the same configuration. Our co-extruded reinforcement netting can be incorporated with nonwoven foam, paper, film, membrane, tissue, and other fabrics to become part of composites used in various industrial and consumer applications. By using co-extrusion netting with adhesive layers, manufacturers and converters may eliminate adhesive steps in their manufacturing and converting processes for specific product applications.