Products & Services

November 25, 2025

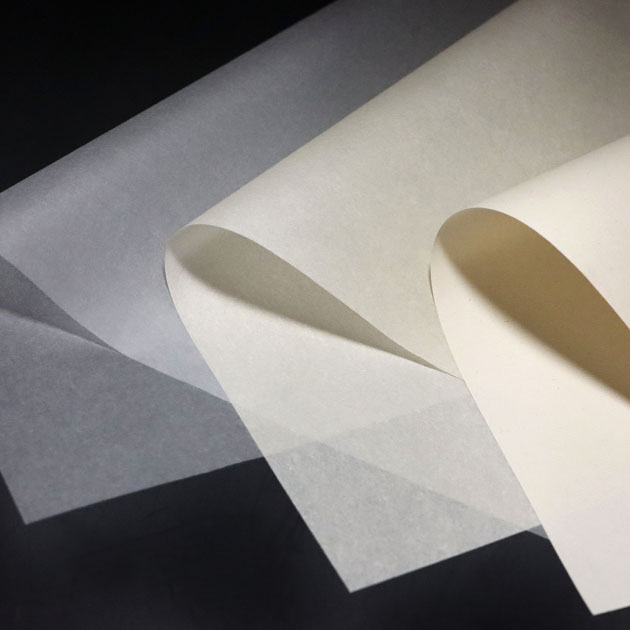

The Paper That's Redefining Spunlace: Inside SWM's Cellulosic Solution

How an SWM-made engineered base spunlace paper is helping nonwovens producers navigate the shift toward plastic-free products without sacrificing performance

When spunlace producers talk about the technical challenges of reducing plastic content, the conversation inevitably turns to a single question: How do you maintain line efficiency and product performance when replacing synthetic fibers with cellulose?

“SWM International believes it has developed part of the answer. The company’s Interlayer Spunlace Paper (ISP) – a wet-laid, 100% cellulosic base paper manufactured in France – is gaining traction among hydroentanglement producers looking to reformulate products in response to regulatory pressure and sustainability commitments”, Alex Boone, VP at SWM.

Unlike conventional pulp webs that can struggle with dimensional stability and runnability, ISP is purpose-engineered for the demanding environment of modern high-speed spunlace lines.

Solving the Stability Problem

The core innovation lies in ISP’s wet-laid structure. Produced on both flat and inclined wire paper lines at SWM’s French facilities, the material delivers controlled formation and porosity that enables efficient energy transfer during hydroentanglement – critical for maintaining production speeds when working with high cellulose content.

The paper’s reinforced cross-directional strength addresses one of the fundamental weaknesses of pure pulp webs: dimensional instability under the mechanical stress of hydroentanglement. This translates directly to improved handling during conversion and greater robustness in end-use applications.

“Available in basis weights from 22 to 60 g/m² and roll widths up to 3,500 mm, ISP accommodates both lightweight consumer wipes and heavier industrial grades. The broad specification range gives formulators flexibility to optimize for different performance requirements without changing their base substrate platform”, says Adrien Bouillot, Product Manager at SWM.

The Washout Advantage

Perhaps ISP’s most significant technical contribution is its extra-low washout behavior. In hydroentanglement, fiber and fines loss into the water circuit creates cascading problems: inconsistent basis weight, increased filtration burden, and potential for deposits on equipment that lead to defects or unplanned downtime.

“Washout is the hidden cost in spunlace production,” explains Philippe Dupont, Product Development Manager at SWM, who has been testing ISP. “When you’re running high-cellulose formulations, keeping fibers in the web rather than in your water system becomes critical for both quality and economics.”

ISP’s engineered structure limits fiber migration, enabling more stable weight control through the hydroentanglement zone and cleaner water loops over extended production runs. For manufacturers operating continuous production schedules, this consistency advantage compounds across thousands of linear meters.

Application Versatility

ISP is finding adoption across diverse end markets. In household and institutional cleaning wipes, it provides the absorbency and softness that cellulose delivers naturally while offering sufficient strength for practical use. Industrial and professional wipes benefit from the durability that comes from ISP’s dimensional stability when combined with appropriate staple fiber blends.

The material is also being specified in personal care and cosmetic applications where brands are actively seeking pulp-rich formulations that align with “natural” positioning. Technical nonwoven producers are incorporating ISP where a cellulosic interlayer improves liquid management or biodegradability characteristics.

SWM offers color-coded ISP variants as well – a seemingly simple feature that addresses practical needs in facilities processing multiple product grades. Visual differentiation reduces the risk of material misidentification in production environments where various specifications might otherwise be indistinguishable.

The Fiber Compatibility Factor

One frequently cited advantage of ISP is its compatibility with diverse fiber blends. Producers can combine the base paper with viscose, PET, lyocell, cotton, or other carded staple fibers, depending on performance requirements and sustainability objectives.

This flexibility becomes increasingly valuable as regulatory frameworks evolve. The EU’s Single-Use Plastics Directive and various Extended Producer Responsibility schemes are creating different compliance pathways. Some manufacturers are pursuing plastic-reduced formulations; others are targeting fully plastic-free concepts. ISP’s adaptability allows producers to navigate these requirements without fundamentally redesigning their process infrastructure.

“We are seeing customers use ISP as a platform to develop product families,” notes Adrien Bouillot. “Same base substrate, different fiber combinations optimized for specific market segments or regulatory requirements. That development efficiency matters when you’re racing to meet compliance deadlines.”

Market Position

While several suppliers offer cellulosic materials for spunlace applications, ISP’s combination of low washout, dimensional stability, and broad specification range positions it as a technical solution rather than simply a commodity fiber source.

SWM’s manufacturing footprint in France – with production capabilities on multiple paper line configurations – provides both capacity and technical variety that can be difficult to replicate. The ability to produce widths up to 3,500 mm accommodates the scale requirements of large spunlace operations without splicing or double-width processing.

As nonwovens producers continue reformulating to meet sustainability mandates while defending product performance, engineered cellulosic interlayers like ISP represent a category that’s likely to see sustained growth. The value proposition is straightforward: enable plastic reduction without sacrificing the runnability and consistency that high-volume manufacturing demands.

For an industry navigating one of its most significant material transitions in decades, that’s proving to be a valuable combination.