Pages

Products

-

![]() Read more

Read moreWrapping Paper for Nicotine Pouches – MODS™

Our mission is to support the transition of the industry towards reduced-risk products and have a positive impact on society thanks to MODS™, our Wrapping Paper for Nicotine Pouches solution.

-

![]() Read more

Read moreWrapping Material for HNB

Our fit-for-purpose solutions address the challenge of the specific feature requirements of HNB, driven by stick design and heating system choices, such as non- combustibility, high tensile strength or barrier effect.

-

![]() Read more

Read moreReconstituted Material for Aerosol Generation

Aerosol generating material is a key element of HNB. The objective is very different than for reconstituted tobacco for cigarette as it is the key contributor of aerosol taste and flavor.

-

![]() Read more

Read moreBase Tipping Paper

Our deep-rooted experience in Base Tipping Paper gives the solid foundation to provide enhanced solutions to convey your brand equity for both combustible and non-combustible products.

-

![]() Read more

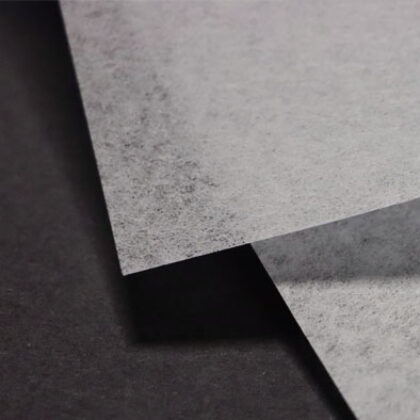

Read moreMembrane Backing Layer – MemBase™

MemBase™ membrane backing layer is a support element that features a unique set of material properties designed to improve runnability in the casting process.

-

![]() Read more

Read moreLightweight Translucent Paper

Expert in lightweight wrapping papers, SWM is committed to provide solutions to replace plastic films and help the packaging industry address environmental and regulatory requirements.

-

![]() Read more

Read moreFiber-Based Solutions for Packaging

Thanks to an innovation spirit, a unique expertise in transforming natural and botanical fibers into smart lightweight papers, SWM meets the needs of a broad range of end-use applications.

-

![]() Read more

Read moreConventional Cigarette Paper

As the tobacco market becomes increasingly competitive and continues to evolve, we offer a wider array of performance characteristics and options for your Cigarette Paper.

-

![]() Read more

Read moreLow Ignition Propensity (LIP) Paper

Thanks to a unique printing process our Low Ignition Propensity (LIP) Paper solutions adhere with regulations to prevent fires caused by burning cigarettes.

-

![]() Read more

Read moreRolling Papers

We offer a wide choice of light- and ultra-light weight Rolling Papers, made of multiple fibre pulp offerings in transparent, white, unbleached and pastel shade coloured.

-

![]() Read more

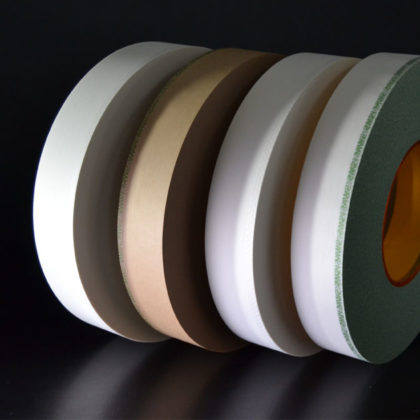

Read morePorous Plug Wrap Paper

The invention of Porowrap®, our Porous Plug Wrap Paper, has widen the range of ventilated filter designs options. It is an essential component of today's ideal filter ventilation systems.

-

![]() Read more

Read moreNon-Porous Plug Wrap Paper

We offer an efficient Non-Porous Plug Wrap Paper fitting all filtering media wrappings.

-

![]() Read more

Read moreTobacco Filter Products – Evolute®

Evolute®, the innovative and alternative filtering media range to accelerate transition to cellulosic fiber-based filters for all tobacco market segments.

-

![]() Read more

Read moreReconstituted Tobacco Filler

Cigarette, Cut Rag, Shisha and RYO manufacturers consider Reconstituted Tobacco Filler as an important element of their blend in addition to the various types of natural tobacco used.

-

![]() Read more

Read moreWrapper & Binder

Modern day machine-made cigars consist of three main components: a filler, which makes up the bulk of the cigar, an inner binder to hold the filler in place, and an outer wrapper, which gives the cigar its distinctive appearance.

-

![]() Read more

Read moreService Offering for HNB

We help the tobacco industry safely and successfully transition to Heat Not Burn (HNB) markets by providing expert services and high-quality components to launch Heated Tobacco Products (HTP) / (THP) or Herbal Heated Products (HHP).

-

![]() Read more

Read moreSterilization Pouches – Medipel™

Medipel™ is a premium cellulose base solution ready to be converted into Sterilization Pouches for hospitals and healthcare facilities.

-

![]() Read more

Read moreOil and Grease Resistant (OGR) Paper – FIVE™

Made of natural and biodegradable fibers, our Oil and Grease Resistant Paper is designed for food contact, offering excellent barrier on both sides and performance even in folded areas, with great resistance to high temperatures.

-

![]() Read more

Read moreFood & Hygiene Wrapping Papers

With a 100% cellulose base, our paper-based wrapping solutions are ideal for various applications such as straws, hygiene and feminine care products. Their features offer high-quality formation and excellent printability.

-

![]() Read more

Read moreTextile Pulp and Botanical Fibers

For over 60 years, we have been refining our process to transform flax and hemp fibers as well as produce botanical fibers to use as the pulp component for specialty and sensory paper materials.

-

![]() Read more

Read moreSeparators for Alkaline Batteries

Over the last 25 years, we have established ourselves as the leading producer of Separator Paper for the global Alkaline Battery supply chain.

-

![]() Read more

Read moreOverlay Paper and Laminates

We are a proven leader in Overlay Paper for furniture, flooring and countertops and we continue to expand our portfolio to meet evolving market needs with consistently high-quality, innovative solutions.

-

![]() Read more

Read moreTechnical Papers

SWM manufactures lightweight uncoated Technical Papers and non-wovens in France and in Brazil.

-

![]() Read more

Read morePaper Marking and Customization

Our state-of-the-art Paper Marking capabilities stamp your brand identity to your thin and ultra-thin paper without additives.